Kensium WMS Optimization

The KensiumWMS optimization suite solves several issues facing large or complex warehouse environments.

- Increasing visibility into which sales orders to convert to shipments given inventory constraints.

- Minimize the number of items to be picked by allowing the ability to pick by UOM.

- Maximizing the items on a shipment by delivering cross-dock capabilities for receiving and manufacturing.

- Controlling pick locations to reduce pick time and efficiency.

- Facilitating restocking of primary pick locations to increase pick efficiency.

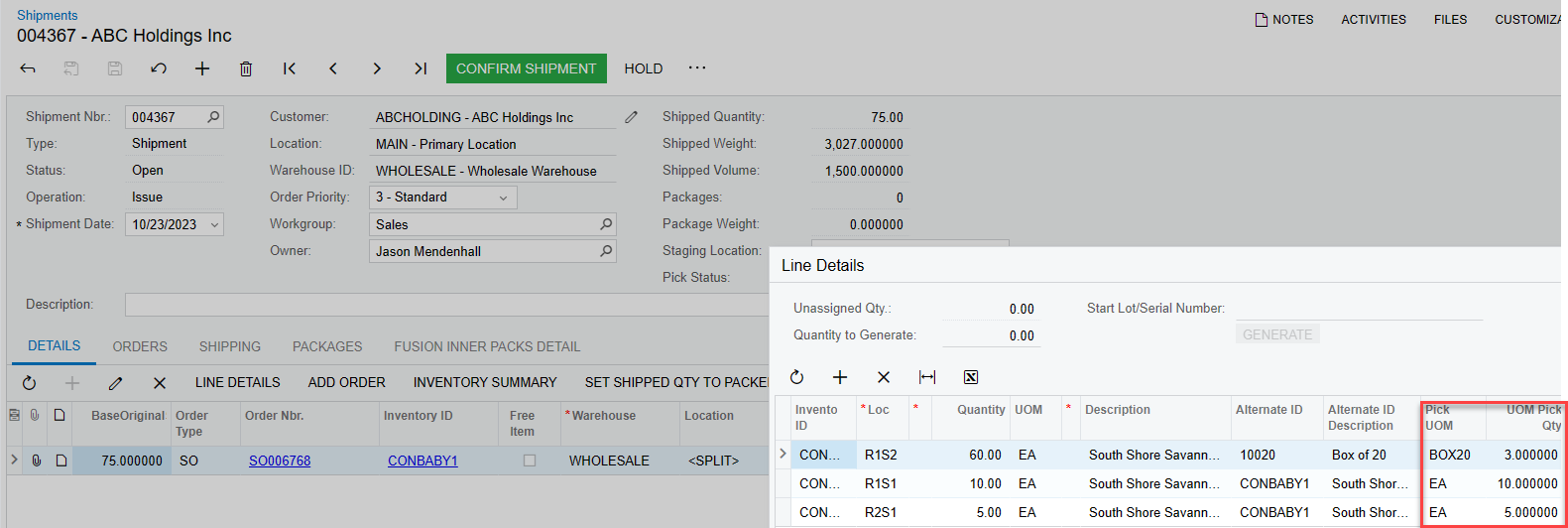

One feature of KensiumWMS Optimization is to minimize the number of items to be picked. Sales orders are typically presented in the quantity of individual items ordered. However, items are generally stocked in various Units of Measure (UOM) in the warehouse. During Acumatica’s Create Shipment routine, KensiumWMS takes the SO quantity and using the UOMs as defined in the Cross Reference tables, determines the minimum “things” to be picked to fill the order quantity. For example, if an item’s case count is 24 and the SO quantity is 100, Kensium will convert the Shipment to 4 cases and 4 individual items.

The Shipment line will reflect the items and order quantity. However, the Line Details for the given line will reflect the location, UOM and quantity for each UOM as determined by Kensium WMS Optimization. Note the Sales Order and the ensuing invoice will reflect the same line items/quantities. Kensium WMS only affects the Shipment.